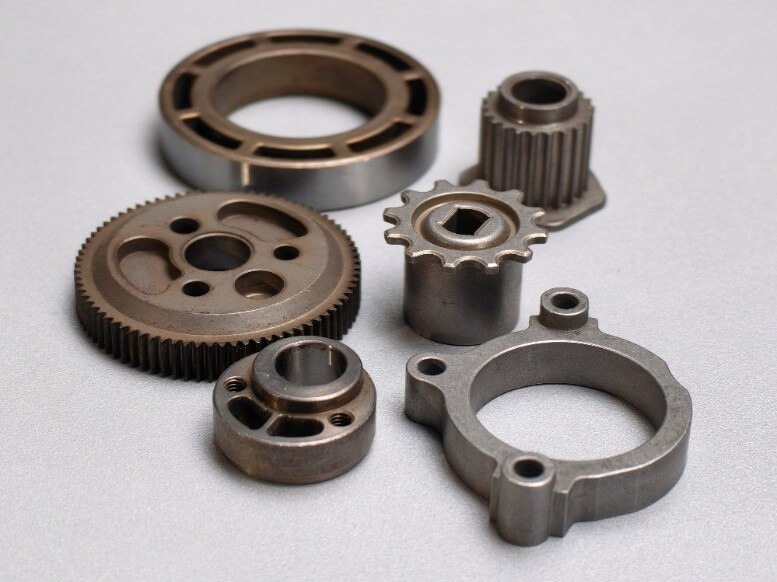

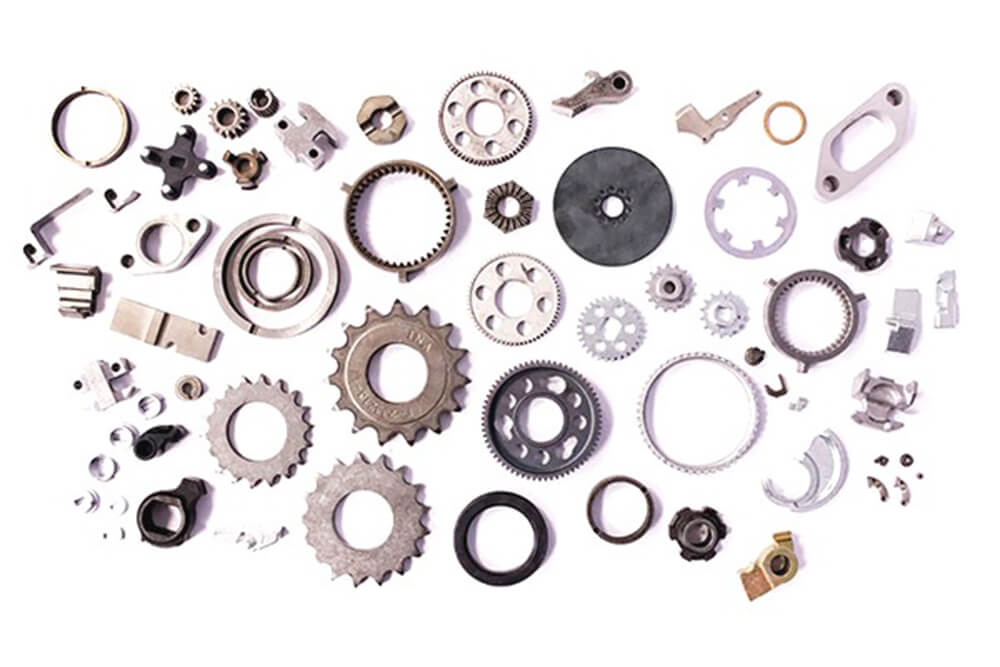

GEVORKYAN’s uniqueness lies in the combination of sintering (powder metallurgy), metal powder injection moulding (MIM) and hot isostatic pressing (HIP) under one roof, which makes it unique in the world.

The company has also added Additive Manufacturing (AM), i.e. 3D printing of metal products, to its portfolio in 2019. In doing so, it has been actively using 3D printing technology for years to 3D print plastic components internally that are used in the maintenance department, eliminating production machine downtime and long lead times for spare parts.

Modern and innovative technologies bring with them lower production costs, variability of shapes and dimensions, large-scale production and reduced environmental impact compared to traditional technologies.